Unlocking Potential: Synthetic Fuels in Modern Military Operations

Synthetic fuels, a revolutionary alternative to traditional fossil fuels, are not just gaining attention but are becoming an urgent necessity across various sectors, including the military. As nations strive to enhance operational capabilities while mitigating environmental impact, adopting synthetic fuels is no longer a choice but a pressing need. This article delves into the urgent integration of synthetic fuels within military forces, showcasing successful examples from Western doctrines and outlining the potential and challenges associated with their widespread adoption. The potential benefits of synthetic fuels in military operations are not just vast but crucial, offering a more sustainable and efficient energy source that could fundamentally transform our approach to warfare.

Scientific Definition of Synthetic Fuels:

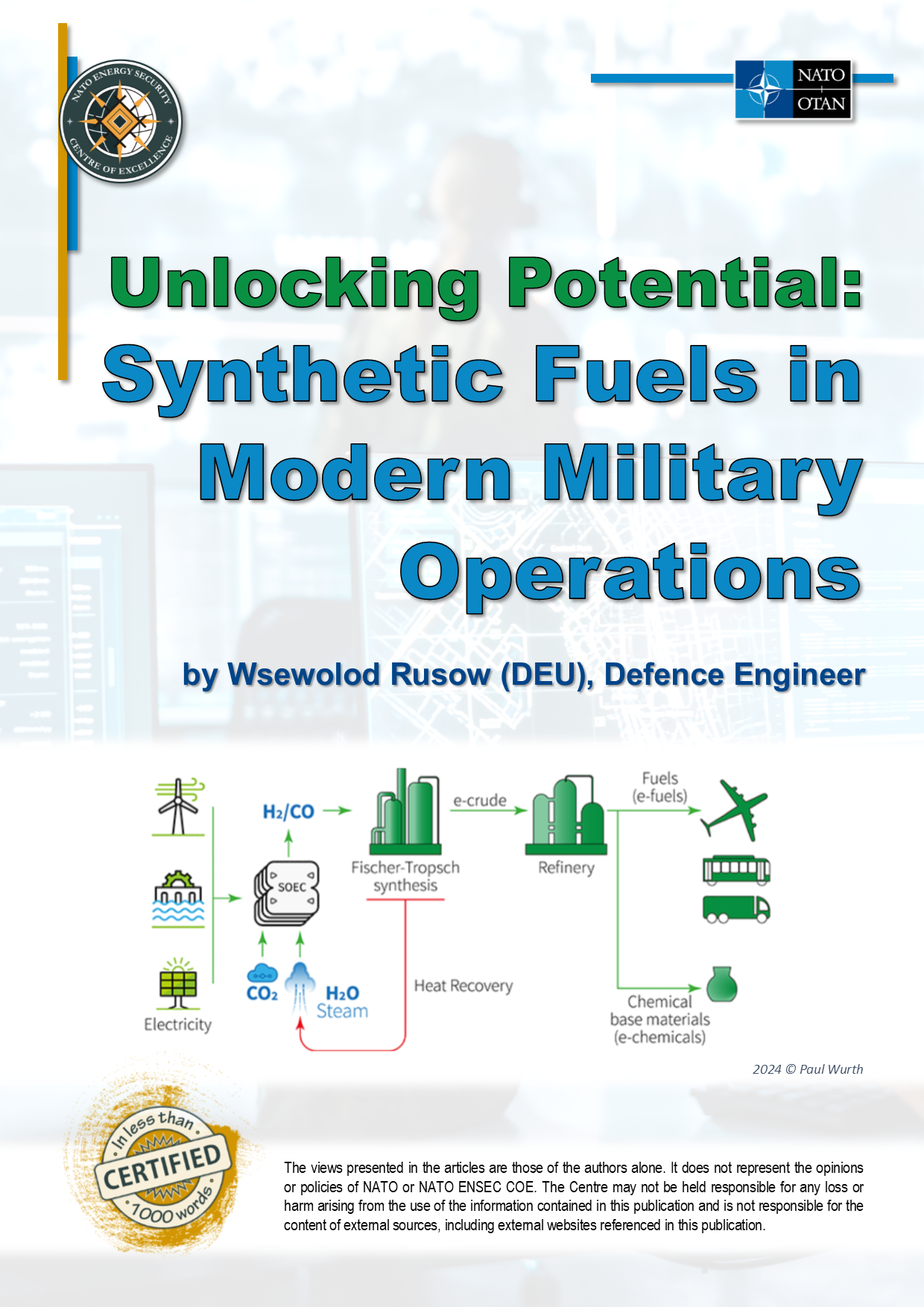

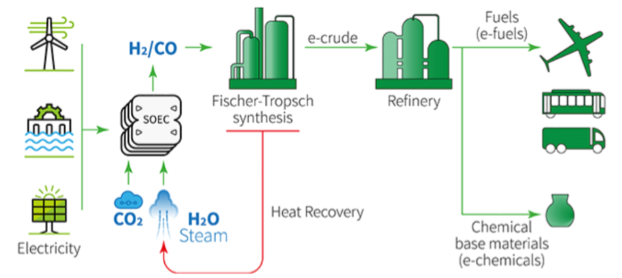

Synthetic fuels, scientifically known as SynFuels, refer to liquid or gaseous fuels produced through artificial chemical processes, typically involving the chemical conversion of carbon-containing feedstocks. However, SynFuel’s origin is SynGas, a gaseous blend commonly composed of carbon monoxide (CO) and hydrogen (H2). The production methods typically include Fischer-Tropsch synthesis or the conversion of renewable resources, resulting in fuels that closely mimic traditional hydrocarbons.

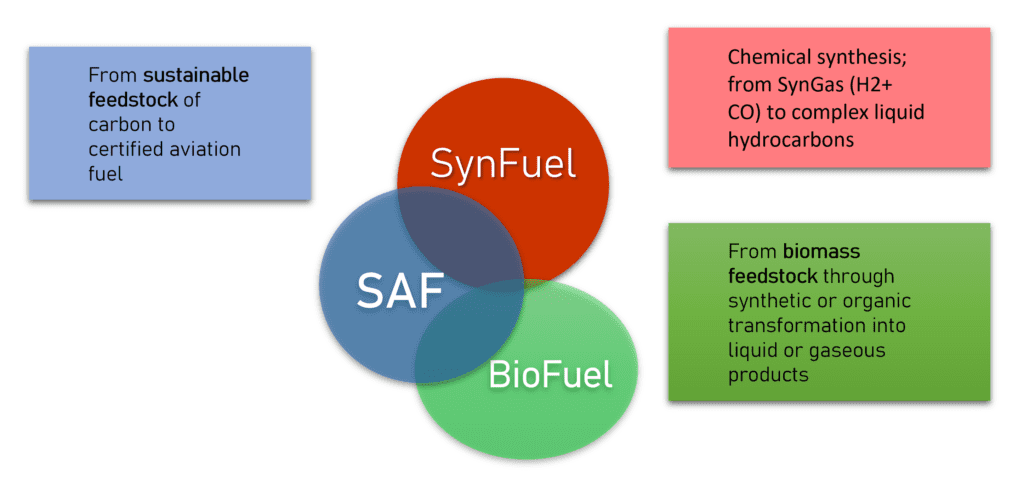

Comparing Synfuels vs. Sustainable Aviation Fuels (SAF):

While sustainable aviation fuels (SAF) fall under the broader category of synthetic fuels, it’s important to note their unique characteristics. SAF encompasses a variety of fuels derived from renewable sources, including biomass, waste oils, and synthetic processes. In contrast, synthetic fuels specifically involve the artificial creation of hydrocarbons through advanced chemical processes and may also incorporate nonsustainable carbon sources like coal for their SynGas synthesis. Understanding these nuances is crucial in comprehending the potential and challenges of synthetic fuels in military operations, which is the primary focus of this article.

That is why not all synthetic fuels, such as coal-based fuels, are sustainable and classified as SAF, as their standard neither determines nor requires sustainable processing of the synthetic components. Based on different production process technologies, eleven types of synthetic jet fuel blending components are currently approved under ASTM D7566, which sets out the specifications and blending limits under separate Annexes. A blending limit of 50% maximum is applicable for most types of synthetic jet fuel. If approached from the perspective of SAF, sustainable aviation fuels must meet the respective sustainability requirements of CORSIA. It is worth noticing that those requirements have been deeply reviewed and put in force from January 2024 by ICAO.

One key advantage of synthetic fuels over other SAFs is their higher potential for larger-scale production, as the industries could rely on the existing fossil fuel distribution network. Synthetic fuels’ compatibility with conventional military vehicles and aircraft minimizes the need for extensive modifications, streamlining the adoption process for military forces. However, while their carbon advantages can be questioned in the case of fossil origin, the energy security component will be increased anyway.

Table 1: Schematic relations of alternative fuels

Synthetic Fuels in Western Military Doctrines:

Western military forces have initiated innovative initiatives to incorporate synthetic fuels into their strategic frameworks. For instance, the United States Department of Defense (DoD) has been actively exploring synthetic fuels to reduce dependency on conventional fossil fuels. Notable achievements include successful test flights using synthetic aviation fuels derived from renewable sources, demonstrating the feasibility of incorporating synthetic fuels into existing military aviation platforms.

In 2021, the University of the Bundeswehr in Munich, in collaboration with the Bundeswehr Research Institute for Materials, Fuels, and Lubricants (WIWeB), conducted a comprehensive study focused on investigating the compatibility of elastomers with synthetic fuel components for potential use in existing systems within the Bundeswehr. Elastomers, serving as seals, hoses, and tank linings in aviation and vehicles, are crucial components, and their behavior with synthetic fuels is a key consideration.

Similarly, the NATO alliance has shown a keen interest in synthetic fuels as part of its commitment to environmental sustainability. Collaborative efforts among member nations have developed and tested synthetic fuels in military vehicles and equipment, showcasing a concerted effort to transition towards cleaner energy alternatives.

The Valuable Potential of Synfuels:

The allure of synthetic fuels lies in their versatility and environmental benefits. Produced through processes like Fischer-Tropsch synthesis or biomass conversion, synthetic fuels can offer a carbon-neutral alternative to traditional hydrocarbons. This characteristic makes them a strategic choice for military forces aiming to reduce their carbon footprint and enhance energy security.

One notable advantage of synthetic fuels is their compatibility with existing distribution and delivery infrastructure and equipment. Military vehicles and aircraft can seamlessly transition to synthetic fuels without significant modifications, allowing a smoother integration process. Additionally, synthetic fuels boast a high energy density, ensuring military operations maintain the required power and endurance without compromising efficiency.

Challenges along the way:

Despite the immense potential, the widespread adoption of synthetic fuels in military forces faces notable challenges. One primary concern revolves around the scalability and cost-effectiveness of large-scale synthetic fuel production. Governments and industries must develop sufficient production and distribution infrastructure for mass production to make synthetic fuels economically viable for military applications.

Figure 1: Syntroleum plant near Tulsa, Oklahoma, in the US (Syntroleum) © AusAirPower.net

Furthermore, ensuring the security and resilience of the synthetic fuel supply chain poses a significant challenge. Military forces rely on a stable and robust fuel supply, and any disruption could compromise operational readiness. Developing a resilient supply chain for synthetic fuels will be crucial to addressing this concern.

Quantifying Carbon Footprint Advantages:

Adopting synthetic fuels by NATO military forces presents a promising avenue for substantial carbon footprint reduction. Synthetic fuels, derived from renewable sources and produced using sustainable methods, offer a carbon-neutral alternative to conventional hydrocarbons. The quantifiable advantage lies in the potential to significantly lower carbon emissions associated with military operations.

Recent studies assume that implementing synthetic fuels in NATO military fleets could considerably reduce carbon dioxide (CO2) emissions. Preliminary estimates indicate a potential decrease of up to 50% in carbon footprint compared to traditional fossil fuels. This quantifiable advantage is theoretical for now and requires experimental verification, but it underscores the transformative potential of synthetic fuels in contributing to NATO’s environmental sustainability goals.

Conclusion:

Synthetic fuels represent a transformative solution for modern military forces striving to balance operational demands with environmental responsibility. The successful integration of synthetic fuels into Western military doctrines demonstrates this innovative energy source’s tangible benefits and potential. Addressing challenges of production scalability, cost-effectiveness, and supply chain resilience will be essential as advancements continue. Also, it is undoubtedly true that synthetic fuels represent only a long-term solution; the journey toward adopting synthetic fuels in military operations holds the promise of enhancing efficiency and contributing to a more sustainable and resilient defense infrastructure for the future.

| ASTM Reference | Conversion process | Abbreviation | Possible Feedstock | Max. Blend Ratio |

| ASTM D7566 Annex A1 | Fischer-Tropsch hydro-processed synthesized paraffinic kerosene | FT | Coal, natural gas, biomass | 50% |

| ASTM D7566 Annex A2 | Synthesized paraffinic kerosene from hydro-processed esters and fatty acids | HEFA | Vegetable oils, animal fats, used cooking oils | 50% |

| ASTM D7566 Annex A3 | Synthesized iso-paraffins from hydro-processed fermented sugars | SIP | Biomass used for sugar production | 10% |

| ASTM D7566 Annex A4 | Synthesized kerosene with aromatics derived by alkylation of light aromatics from non-petroleum sources | FT-SKA | Coal, natural gas, biomass | 50% |

| ASTM D7566 Annex A5 | Alcohol to jet synthetic paraffinic kerosene | ATJ-SPK | Ethanol, isobutanol, and isobutene from biomass | 50% |

| ASTM D7566 Annex A6 | Catalytic hydro thermolysis jet fuel | CHJ | Vegetable oils, animal fats, used cooking oils | 50% |

| ASTM D7566 Annex A7 | Synthesized paraffinic kerosene from hydrocarbon-hydro processed esters and fatty acids | HC-HEFA-SPK | Algae | 10% |

| ASTM D7566 Annex A8 | Synthetic Paraffinic Kerosene with Aromatics | ATJ-SKA | C2-C5 alcohols from biomass’ | |

| ASTM D1655 Annex A1 | Co-hydroprocessing of esters and fatty acids in a conventional petroleum refinery | Vegetable oils, animal fats, used cooking oils from biomass processed with petroleum’ | 5% | |

| ASTM D1655 Annex A1 | Co-hydroprocessing of Fischer-Tropsch hydrocarbons in a conventional petroleum refinery | Fischer-Tropsch hydrocarbons co-processed with petroleum | 5% | |

| ASTM D1655 Annex A1 | Co-Processing of HEFA | Hydro-processed esters/fatty acids from biomass’ | | 10% |

Table 2: certified SAF origins (ICAO) 2023

The views presented in the articles are those of the authors alone. It does not represent the opinions or policies of NATO or NATO ENSEC COE. The Centre may not be held responsible for any loss or harm arising from the use of the information contained in this publication and is not responsible for the content of external sources, including external websites referenced in this publication.